Ice and Rain Protection

- James Albright (a former G450 driver)

Updated: 2012-01-01

[G450 AOM, §2A-30-10] Ice protection systems on the G450 employ either warm engine bleed air or heat generated by electrical resistance to prevent the formation of ice on critical structures and installations.

Everything here is from the references shown below, with a few comments in an alternate color.

The ice and rain protection system is divided into the following subsystems:

The basic idea since the GII has been that we need to heat the cowl inlets with pneumatic air to keep the engines free of ice, we need to heat the leading edges of the wings with pneumatic air to keep them free of ice, we need to electrically heat the windows and the pitot tubes to keep them free of ice, and we don't worry about the tail because ice up there has never been a problem. Along the way Gulfstream has made each of the systems better and added ice detection. In the earlier days of the GV we left the anti-ice switches in AUTO and let the system do its thing. No more, the lawyers got involved so now:

Operate in AUTO

When it looks like you are going to need anti-ice, turn the cowls to ON.

Once ice is detected, turn the wings to ON.

Leave them ON until the ice detector says you are out of icing conditions

Ice Detection System

General Description

[G450 AOM, § 2A-30-20, 1.] Since the exterior surfaces of the aircraft are difficult to view from the cockpit window while in flight, the crew is forced to rely upon observation of the limited features within the field of view to detect the presence of ice on the aircraft. To aid the crew in the timely recognition of icing on the aircraft exterior, the G450 has two ice detectors, one on each side of the aircraft, installed below the cockpit windows.

Ice Detector Probes

[G450 AOM, § 2A-30-20, 2.A.] The ice detectors probes incorporate a vibrating sensor element extended into the airstream flowing around the fuselage. The element length is sufficient to avoid the frictional heating effects immediately surrounding the aircraft structure. The sensor vibrates in clear air at an extremely high frequency range (approximately 40,000 Hz); however, if ice accumulates on the sensor, the frequency of the vibrating element will show a decrease proportional to the amount of accumulation.

AUTO Mode "On"

[G450 AOM, § 2A-30-20, 1.] The WING and COWL selector switches on the ANTI-ICE panel on the cockpit overhead can be positioned to AUTO. If AUTO is selected, ice detector signals can be used to automatically activate wing and engine cowl anti-ice bleed air flow, provided the aircraft is within the prescribed altitude envelope for automatic operation. Because extracting bleed air from the engine decreases engine thrust, automatic anti-icing is not available below fifteen hundred (1,500) feet where full engine capability is reserved for takeoff and landing. However, if automatic anti-icing had been selected at a higher altitude, it remains operational in descent below 1,500 feet, since engine thrust requirements are minimized in descents, and engine cowls and wing surfaces must be kept clear of ice in preparation for landing.

AUTO Mode "Off"

[G450 AOM, § 2A-30-20, 2.A.] When the ice detectors no longer sense the presence of ice, the wing and cowl anti-ice bleed valves are signalled to close after a time delay. The time delay is incorporated into the control software of the ice detectors in order to ensure that all ice accumulations on the wings and engine cowls have been dissipated. Automatic anti-ice protection is terminated in the following sequence:

ICE DETECTED Signal — 1 minute

Cowl Anti-Ice Signal — 3 minutes

Wing Anti-Ice Signal — 5 minutes

Limitations

[G450 AM, § 1-30-20] Operation of wing anti-icing is required if icing conditions are imminent, or immediately upon detection of ice formation on wings, winglets, or windshield edges.

[G450 AM, § 1-30-30] Automatic anti-ice is inhibited above 35,000 ft. If anti-ice protection above 35,000 ft is required, it must be manually selected.

Cowl Anti-Ice System

The engine cowl anti-ice system takes air from the bleed air duct and sends it to the intake cowls through dedicated valves that are, essentially, spring loaded open. (There is more to it than that, but you can think of them that way to keep things simple.) A pressure sensor is used to monitor system performance. Unlike many Gulfstreams, on most G450s the engine's bleed air valve needs to be open for the engine's cowl anti-ice to operate and you cannot operate the anti-ice on one engine using air from another source. Most, because this has changed on later G450s.

[G450 AMM, §30-21-00 ¶1.A.] The engine inlet anti-ice system uses bleed air from the engine compressor and routes it to the engine inlet cowls. An anti-ice duct supplies air from the compressor to the rear bulkhead of the engine inlet cowl. The cowl anti-ice control valve in the anti-ice duct controls the flow of air. The position of the anti-ice control valve is monitored by switches inside the valve. The switch outputs are supplied to the Modular Avionics Units (MAUs) to monitor for a cowl anti-ice control valve failure.

The bleed air comes from the 7th and 12th stage compressors of the engine downstream of the engine bleed pressure regulating shutoff valve, shown above. That is important for two reasons. First, the engine bleed switch has to be on for it to get engine anti-ice air. Second, the air does not go through the precooler and has a very short trip to the cowl inlet; it will be hotter than the bleed air duct manifold air.

Though it isn't documented anywhere, later G450s have removed the check valve that prevents bleed air coming from outside the engine to reach the cowl anti-ice. You can see that in the following photo. The left engine cowl anti-ice has pressure. (It isn't green because that engine is off an its FADEC isn't reporting the anti-ice status.

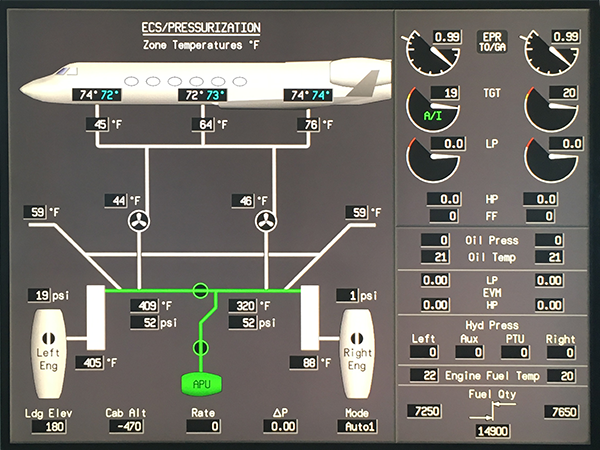

Photo: G450 ECS/Pressurization System Synoptic, APU Bleed pressurizing left engine cowl anti-ice, photo courtesy Lars Møller.

Cowl Anti-Ice Control Valve

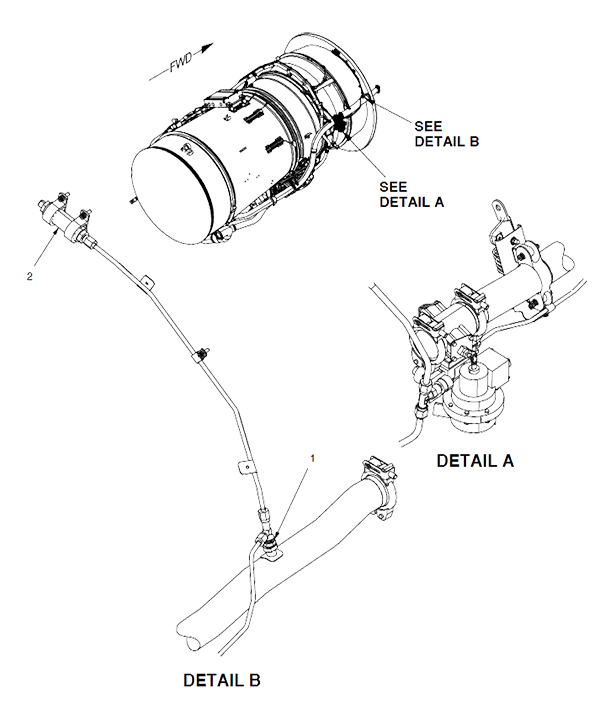

Figure: G450 Cowl Anti-Ice Control Valve, (G450 MM, §30-21-01, figure 502)

[G450 AMM, §30-21-00 ¶3.A.] The cowl anti-ice control valve is mounted on the upper right side of each engine. The valve contains an internal two pole, two position switch used by its respective MAU for display on the CAS. When the cowl anti-ice control valve solenoid is energized, the valve butterfly closes. When the solenoid is de-energized, the valve is opened by bleed air pressure.

[G450 AMM, §30-21-00 ¶4.A.] The cowl anti-ice control valve is powered by the L COWL ANTI-ICE circuit breaker. The left cowl anti-ice control valve is controlled by the three position (ON, OFF and AUTO) ANTI ICE - L COWL rotary switch located in the ANTI ICE section of the cockpit overhead panel.

When the ANTI ICE - L COWL switch is in the ON position, the left cowl anti-ice control relay is de-energized. The relay removes 28 Vdc from the cowl anti-ice control valve solenoid. This de-energizes the valve solenoid and allows the valve to open. If the valve does not open, an internal switch sends a discrete signal to MAU No. 1, causing a valve failed message to be displayed on the CAS.

When the ANTI ICE - L COWL switch is in the OFF position, 28 Vdc is applied to the left cowl anti-ice control relay, energizing it. The relay applies 28 Vdc to the cowl anti-ice control valve. This energizes the valve solenoid and causes the valve to close. If the valve does not close, an internal switch sends a discrete signal to MAU No. 1, causing a valve failed message to be displayed on the CAS.

[G450 Operating Manual, §2A-30-30, ¶ 1.] If the flight crew selects the left or right COWL switch to OFF, twenty-eight volt direct current (28v DC) power from the Main DC bus (left bus for left engine, right bus for right engine) is routed to a solenoid within the valve to maintain the valve in the shut position. . . . However, if the ice detectors sense the formation of ice on the airplane with the COWL selector switch in AUTO, or if the crew manually sets the selector to ON, main DC power is removed from the solenoid in the TAI control valve, and the pressure of the engine bleed air will force the valve open, directing warm air to heat the engine cowl. The control circuit is designed open the engine TAI valve in the event of electrical power loss to preserve the integrity of the engine intake airflow.

This valve will default to the open position if electrical power is removed and pneumatic pressure remains upstream of the valve.

The G450 AMM says it takes air pressure to open the valve, the FSI Maintenance Training Manual says it takes air pressure to close the valve. The diagrams, which are FSI only creations, seem to indicate the valve is electrically controlled and pneumatically driven. I've turned the cowl anti-ice switches on with no bleed pressure available and the CAS indicated the valves were open. Bottom line: the cowl anti-ice valves appear to be spring-loaded open and will attempt to close if given an electrical signal and bleed pressure.

Inlet Cowl Ducts

[G450 AOM, §2A-30-30 ¶1.A.] Within each engine nacelle, air is taken from the Bleed Air Supply manifold and routed forward through ducting and a control valve to a circular tube located inside the air inlet cowling. The circular tube is perforated with small openings to distribute the warm pressurized air within the entire circumference of the engine cowl. The air exhausts through a grill opening on the underside of the engine cowl.

Monitoring

[G450 AOM, §2A-30-30 ¶1.A.] Pressure is monitored rather than temperature because the TAI bleed air is drawn from the bleed air system manifold, and the temperature of the bleed air within the manifold varies with engine power setting and whether the seventh compressor stage, twelfth compressor stage or a combination of both is supplying the bleed air manifold. Although the pressure transducer is capable of monitoring a pressure range from 0 - 75 psi, the normal pressure within the duct with the cowl anti-ice operating is between 0 - 33 psi. If the engine is running and cowl anti-ice is selected on and the bleed air pressure to the cowl is between 1.6 and 33.0 psi the band is shown in green. If bleed air pressure is less than 1.6 psi or greater than 33.0 psi the band is shown in amber.

The Gulfstream manuals don't list a specific pressure for the cowl anti-ice. The FSI Maintenance Training Manual (pg. 30-41) say the valve regulates pressure to 19 ±3 psi. That seems to be true, I've seen that in every scenario except on the ground at idle, where I've seen around 10 psi.

Limitations

[G450 AFM, §01-30-30]

Use of cowl anti-icing is required for taxi and takeoff when Static Air Temperature (SAT) is 10°C (50°F) or below and visible moisture, precipitation, or wet runway are present. When taxiing or holding on the ground at low power in temperatures less than 1°C (34°F), engine operation of 85% LP for two (2) seconds is recommended just prior to takeoff and at intervals of not more than sixty (60) minutes. Under these temperature and moisture conditions, accelerate the engines to 85% LP, pause for one (1) minute, then resume operations.

Use of cowl anti-icing system is required in flight as indicated in Figure 1: Temperature Range For Cowl Anti-Icing, when visible moisture or precipitation is present or when signs of icing are observed. Ice accretion may be observed on wings or windshield edges.

Increase in engine vibration levels may develop in icing. The fan should normally shed the ice and vibration will return to normal. To assist in shedding ice, if high vibration occurs and operational circumstances permit, one engine at a time may be quickly retarded to idle, held there for five (5) seconds and then accelerated to 85% LP for two (2) seconds, the power lever may then be returned to its original position.

Automatic anti-ice is inhibited above 35,000 ft. If anti-ice protection above 35,000 ft is required, it must be manually selected.

Figure: Temperature Range For Cowl Anti-icing, (G450 AFM, §01-30-30, figure 1)

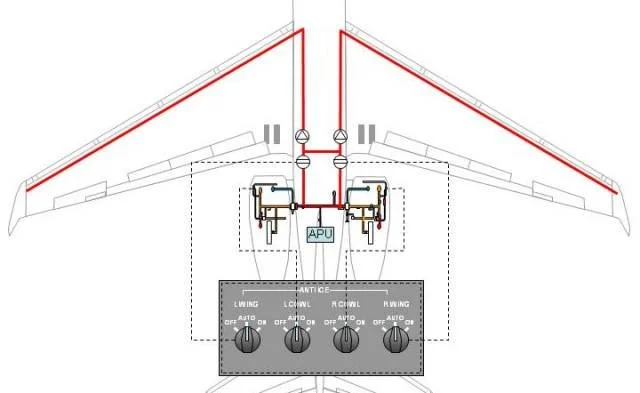

Wing Anti-Ice System

The wing anti-ice system takes 400°F or 500°F air and sends it to the leading edges of the wings through two valves that spring-loaded closed. There is an always open cross-over duct and you can manipulate bleed pressure to ensure both wings are heated. A series of sensors and switches control the entire operation and let you know when things go awry.

Unlike the cowl anti-ice, turning the wing anti-ice can rob you of VVI in the climb. The book clearly says, "if icing conditions are imminent or immediately upon detection." So I leave them in AUTO and if detected, I turn them on.

Trouble? If you know the control valve is spring-loaded closed, that the manifold temperature should be 400°F when both wing anti-ice systems are on or 500°F when only one engine's bleed air is available, you will be able to see through many of the abnormals where the wing's temperature just isn't making sense.

[G450 AOM, §2A-30-40] The leading edge of the wing is warmed to approximately 130°F with hot engine bleed air to prevent the accumulation of ice and consequent disruption of airflow over the wing that could lead to a rapid increase in the stall speed of the airplane.

Air Source

[G450 AOM, §2A-30-40 2.A.] Hot pressurized air is drawn from the 7th and/or 12th stage of the compressor of each engine as a source of anti-ice bleed for the respective side wing (right engine for right wing, etc.).

Seventh stage air is augmented by 12th stage air when wing anti-ice is operating to provide a bleed air manifold temperature of 400°F.

Anti-Ice Control Valve

[G450 AOM, §2A-30-40 2.A.] The wing anti-ice control valve is opened or closed by the Bleed Air Controller (BAC) in response to the position of the selector switches on the ANTI ICE panel on the cockpit overhead (OFF, AUTO or ON) and the temperature sensors within the wing leading edge.

The control valve has a solenoid and a torque motor. The solenoid powers the valve in response to a selector switch ON command or an ice detector command if the selector switch is positioned to AUTO. The temperature sensors communicate with the BAC, that in turn operates the torque motor of the valve to open or close the anti-ice control valve to maintain the wing leading edge at a temperature of 130 ±10°F.

[G450 Maintenance Manual §30-11-00, ¶ 3.B.] The wing anti-ice control valve is a 3 inch diameter, spring-loaded closed, modulating pressure regulator and shut-off valve mounted in the left / right bleed air manifolds. When commanded to open, a dc voltage is applied to the valve torque motor. Pressure and flow are regulate by the BAC controlling the current level to the torque motor. In the OFF configuration, no current is applied to the valve torque motor. The reference regulator pressure is blocked. Power is removed from the shut-off solenoid. The actuator spring closes the butterfly to the full closed position.

The valve defaults to the closed position when electrical power is removed.

Ducting

[G450 AOM, §2A-30-40 2.A.] The 400°F air is routed forward to each wing through the wing anti-ice control valve and ducting beneath the cabin floor.

Crossover Duct

[G450 AOM, § 2A-30-40 2.A.] A crossover duct is installed between the two supply ducts to allow a single engine to supply heated air to both wings if necessary. One way check valves upstream of the crossover duct prevent the flow of bleed air back to the inoperative engine or anti-ice control valve. When only one engine bleed air source is available for wing anti-ice, the BAC of the remaining engine increases the temperature within the bleed air manifold to 500°F by decreasing the flow of fan stage air through the pre-cooler.

Temperature Sensors

[G450 MM, §30-11-00 ¶4.A.] The wing anti-ice temperature sensors operate when there is electrical power on the aircraft, whether wing anti-ice is selected to on or not. When the wing anti-ice system is operating, the BAC varies the open cross section of the control valve to maintain the wing leading edge at the desired temperature of 130°F. Each BAC transmits wing temperature data to the respective MAU (left wing to MAU No. 1, right wing to MAU No. 2). The MAUs format the temperature information for display on the ECS / Pressure synoptic window display.

[G450 MM, §30-11-07 ¶1.A.] The left and right wing anti-ice temperature sensors are located under the left and right wing leading edge access panels (gap band No. 2).

Overheat Switches

[G450 MM, §30-11-00 ¶4.A.] Three temperature overheat switches and one underheat switch in each wing provide protection for the anti-ice system. The overheat switches close when the temperature in the wing bleed air return exceeds 180°F. Overheat switch closure is reported to the MAU (left wing to MAU No. 1, right wing to MAU No. 2) for display as an amber CAS message reading Wing Hot, L-R. The overheat switches are located inboard at gap band No. 1, adjacent to the temperature sensor at gap band No. 2 and toward the outboard section of the leading edge at gap band No. 3. The underheat switch is part of the overheat switch assembly at gap band No. 2. The underheat switch closes when the temperature is greater than 100°F (37.7°C). The underheat switch opens when the temperature drops below 80°F. Unlike the overheat switches, an underheat condition is reported to both MAU No. 1 and MAU No. 2. This is done for redundancy since each wing has only one underheat switch. The MAUs signal the underheat condition as an amber Wing Temperature Low, L-R CAS message. The low temperature message is inhibited for 2 minutes after the wing anti-ice is selected to on (either manually or automatically). This allows bleed air to reach the wing leading edge and warm the supply and return sections of the duct.

Operation

[G450 MM, §30-11-00 ¶4.A.] When the wing anti-ice system is activated, there is a 2 minute delay programmed into the MAU software which allows the bleed air flowing into the left and right wing ducts to raise the ambient duct temperature to greater than 100°F. This 2 minute temperature transition period is depicted as blue on the synoptic page. After 2 minutes, if the wing duct temperature is less than 100°F, an amber duct will be depicted on the display portion of the synoptic page and the actual duct temperature will be indicated. After 2 minutes, if the wing duct temperature is greater than 100°F, but less than 180°F, a green duct will be displayed and the actual temperature will be indicated. Anytime after system activation, the duct temperature becomes greater than 180°F, an amber duct will appear and the actual duct temperature will be indicated.

Limitations

Operation of wing anti-icing is required if icing conditions are imminent, or immediately upon detection of ice formation on wings, winglets, or windshield edges.

Windshield & Window Ice Protection

[G450 AOM, § 2A-30-50 ¶1.] The front windshields and side windows of the cockpit are heated to prevent the formation of ice and prevent fogging when operating at the low outside air temperatures associated with high altitudes or during conditions of high humidity. The front windshields are a composite sandwich made up of layers of chemically strengthened glass, urethane and polyvinyl butyral films. The side windows are composed of two layers of stretched acrylic separated by a vinyl film. A transparent but electrically conductive chemical oxide coating is applied to the inner face of the outer layers of both the windshield and side windows. When alternating current (AC) is applied to the conductive coating, the resistance of the coating causes an increase in heat. The amount of heat produced within the windshield and side window layers is controlled by maintaining the resistance within a specified range.

Two pushbutton switches on the WINDSHIELD HEAT panel on the copilot side of the cockpit overhead control the application of power to the cockpit windows. Each pushbutton controls a Windshield Heat Control Unit (WHCU) that directs AC power to both a windshield panel and a side window. The left pushbutton controls the WHCU for the pilot windshield and copilot side window heat, and the right pushbutton selects the WHCU for the copilot windshield and pilot side window heat. Four blue indicator lights, one for each heated window, are located above the switches and illuminate when power is applied to heat the respective windshield / window.

The windows in the passenger compartment are also heated in a manner similar to the cockpit side windows to prevent fogging and to preserve passenger visibility at high altitudes.

References:

Gulfstream GV, GV-SP, GV-SP (G550), GV-SP (G500), GIV-X, GIV-X (G450), GIV-X (G350) Master Minimum Equipment List, Revision 07, February 4, 2010.

Gulfstream G450 Aircraft Operating Manual, Revision 35, April 30, 2013.

Gulfstream G450 Airplane Flight Manual, Revision 36, December 5, 2013

Gulfstream G450 Maintenance Manual, Revision 18, Dec 12, 2013