Unscheduled Maintenance Checks

- James Albright (a former G450 driver)

Updated: 2016-12-19

Our pilot manuals seem to be silent on the subject of "unscheduled maintenance." But you need to keep in mind there are times when you need to get a mechanic when you weren't planning to:

We seem to know when something we did, something someone did to us, or just something in general will require an airplane inspection. But some of these you may not know about. Have you ever told ATC you just rode through severe turbulence? Well now you must get the airplane inspected. And there are more things just like that.

The following is not presented as a "how to" for mechanics, but as a primer for pilots to understand the scope of the needed inspection. Read on . . .

Everything here is from the references shown below, with a few comments in an alternate color.

Bird Strike

Photo: Bird on Salisbury Beach, MA, (Eddie Photo)

[G450 MM, §05-50-00, ¶18]

Inspection

Carry out a complete check of the aircraft surfaces and all components which protrude from it, to include windshields, horizontal, vertical and wing leading edges.

Inspect landing gear struts, electrical harnesses, hydraulic lines, wheels, tires, taxi lights, doors and rods for general condition and damage.

Inspect the engine nose cowls and engine cowl doors for general condition and damage.

If pilot reports any failure or a circuit breaker has tripped, this can be the result of mechanical damage to electrical components. Carry out a visual and functional check of affected system.

If any damage is found, contact Gulfstream Technical Operations.

Follow On

Inspect for presence of foreign objects.

Record all maintenance actions in accordance with current governing authority.

Bruce Lighting System Failure

Photo: G450 Interior, (Eddie Photo)

[G450 MM, §05-50-00, ¶13]

The "Bruce Industries" cabin lights are basically all of the fluorescent bulbs. If any component fails, an involved inspection is required that looks for evidence of overheating, improper connector locking, missing components, electrical arcing or carbonization. You can, alternatively, deactivate and placard the system as INOP.

Cabin Pressurization Exceeds Limits

Photo: G450 TROV and PRV, (Eddie Photo) it stand out

[G450 MM, §05-50-00 ¶12]

This inspection should be performed if cabin differential pressure has exceeded 10.00 psi.

Should differential pressure exceed 15.72 psi, contact Gulfstream Technical Operations for disposition and assistance.

If discrepancies are found in this procedure, contact Gulfstream Technical Operations for disposition and assistance.

This is a rather involved procedure, you shouldn't pawn this off to a generic A&P mechanic. You will need a Gulfstream expert.

Flap Airspeed Exceedance

Photo: G450 Flaps and Stab

This procedure requires everything in the system be checked for scoring, gouges, wrinkles, looseness, cracks, distortion, missing components or other signs of damage. That includes each flap track, rollers, assemblies, gearbox, torque shafts, pillow blocks, wing rear beam, jackscrew actuators and actuator housing.

Fire Bottle Discharge

Photo: Fire bottles

[G450 MM, §05-50-00, ¶16]

If the fire bottle is discharged for any reason, it has to be replaced and the shuttle valve that connects it to the engines must be inspected.

Hail Damage

Photo: Hail damage

G450 MM, §05-50-00, ¶ 3]

This inspection is pretty much what you would expect, a visual check of just about everything for distorted or dimpled panels, delamination, cracks, or broken parts.

Hard or Overweight Landing

Photo: G450 Main landing gear prior to landing, (Eddie Photo)

[G450 MM, §05-50-00, ¶7]

This is a fairly long and evolved inspection. It begins thusly:

An immediate check of grease marks on shock struts should be made. If main gear shock struts compressed within 1/2 (0.500) inch of maximum available travel and nose gear compressed to within 1 (1.000) inch of the available travel, then this is evidence that limit vertical loads have been exceeded.

Some of the questions will be for the pilot. What it a two-point or three-point landing. Were there side loads applied to the main landing gear? What was the ground speed at touchdown?

The aircraft will need to be jacked and much more than the landing gear will have to be inspected. The cabin windows and baggage door, for example, must be examined for wrinkles, buckling, and popped rivets. The MAU will record vertical and lateral loads and the maintenance manual presents acceptable loads versus weight. (Anything less than 1.7G is generally okay at all weights. At lower weights the graph goes up to 2.3 G.

High Wind Gusts on Gust Lock

Photo: Gust lock handle, (Eddie Photo)

[G450 MM, §05-50-00, ¶11]

This inspection requires access to several of the lock mounting brackets, crank assemblies, latch hooks, and other components. Of special note, one of the floorboards and the cockpit pedal panel access panels have to be removed. This is not a quick check.

Lightning Strike

Photo: Cloud-to-cloud lightning

[G450 MM, §05-50-00, ¶2]

Mechanics will need to know the following: Did you observe the strike and if so, where was it? Was the landing gear extended? What about the flaps? What about the spoilers?

The check is, for the most part, a visual inspection of the airplane. If a strike on the engines is suspected, the engine check can be a bit more involved.

Nose Wheel Steering Overtravel

Photo: G450 nose wheel overtravel indicator, (Eddie Photo)

[G450 MM, §05-50-00, ¶8]

This inspection involves removing the steering collar assembly covers, removing and checking the shear pin for damage, and reinstalling everything if no damage is found. The pop-up indicator is reset by inserting a thin rod into an access hole while pushing the pin down.

Residual Deicing/Anti-icing fluid

Photo: Pretakeoff contamination check, (Eddie Photo)

[G450 MM, §05-50-00, ¶17]

Aircraft exposed to anti-icing fluids should be subjected to periodic inspections for fluid residue and any residue found should be removed in accordance with this procedure. The frequency of the inspections should be based on each operator’s experience after at least one winter season worth of data. For the period of time prior to accumulating sufficient inspection data to define the frequency appropriate to the operator’s circumstances the following schedule should be utilized. Before the winter season any aircraft that has been previously treated with Type II, Type III or Type IV deicing / anti-icing fluids in previous years should be inspected and cleaned as outlined in this procedure. After the initial inspection the process should continue as long as the aircraft is subjected to Type II, Type III or Type IV deicing / anti-icing fluids unless a two step process is used.

If an aircraft has been inspected and cleaned as outlined in this procedure and it is not exposed to deicing / anti-icing fluids no further inspection will be required until the aircraft is exposed to the fluids again. Some operators will find the need to inspect more frequently and Gulfstream encourages the inspections to be performed as frequently as practical until sufficient data has been accumulated to define the appropriate frequency.

The inspection involves moving the flaps full down and rotating the aileron trim full right before removing several access panels and conducting a visual inspection of aileron, elevator, and stabilizer areas.

Runway Departure

Photo: G550 N535GA, (NTSB Photo)

[G450 MM, §05-50-00, ¶10]

This inspection requires the wheels and tires be removed, inspected, and replaced if necessary. Brakes, landing gear, and all surrounding areas are also inspected.

Severe Turbulence

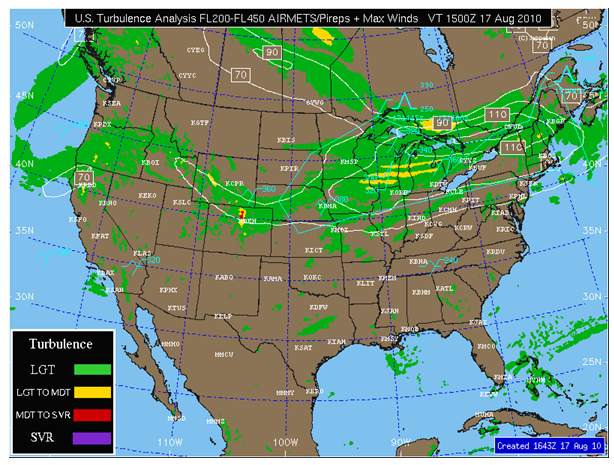

Photo: Turbulence advisories

[G450 MM, §05-50-00, ¶4]

This is a long and involved inspection that requires floorboards and other access panels be removed. You shouldn't expect a quick "once over," this will take a day, at least.

Tire Damage

Photo: Excessive tire wear, (Goodyear tire manual)

[G450 MM, §05-50-00, ¶15] Replace tire if any of the following defects exist:

Fully worn tires

Rubber blisters in upper and lower sidewall

Splits at base of tread groove

Open tread join

Side creasing or buckling

Bulges in the crown area or sidewall

Skid burns or scalds through not more than one cord layer

Leaking tire

Deflated tire on axle (both tires on same axle should be replaced)

Main wheel tires subjected to an abandoned or rejected takeoff requiring the application of maximum braking

Local damage in bead region including any damage to bead chafer and minor damage to casing cords which does not penetrate more than one ply (layer of casing cords beneath bead chafer)

The inspection call for looking for evidence of any foreign objects.

Tire Failure

Photo: Tire abuse

[G450 MM, §05-50-00, ¶9]

This inspection is quite a bit more involved than the previous check. It requires a check of all components, hydraulic lines, electrical harnesses, the structure, the skin, and basically anything that could have been damaged by flying tire debris.

Unscheduled Engine Inspections

[G450 MM, §05-50-00, ¶1]

This inspection depends on what you suspect and the procedure farms out to other sections of the maintenance manual. Categories include: surge, ingestion of volcanic ash, bird strike or slush ingestion, shock loading, snow and ice before starting, high vibration, lightning strike, and bypass duct blockage.

Volcanic Ash

Photo: Alaska volcano

[G450 MM, §05-50-00, ¶6] Volcanic ash particles are usually less than 5 microns and very abrasive. Ash can penetrate all orifices and cause erosion or etching on the surface. Ash particles can accumulate on all lubricated surfaces, in all corners and can cause contamination of all system filters. It is not possible to determine the level of damage volcanic ash contamination can cause. Therefore a full aircraft inspection is necessary to determine the extent of contamination.

This is a very long and detailed inspection, but it may not be long enough! Volcanic ash can get into everything and the damage can be more extensive than you might first think.

References:

Gulfstream G450 Maintenance Manual, Revision 18, Dec 12, 2013